Tubes: production at full capacity

After a period of machinery fine tuning and optimization of our practices and processes, we achieve the targets set about prodctivity, timing and quality results. This is an important consolidation of the effort started in 2019, in the year of our 50th anniversary.

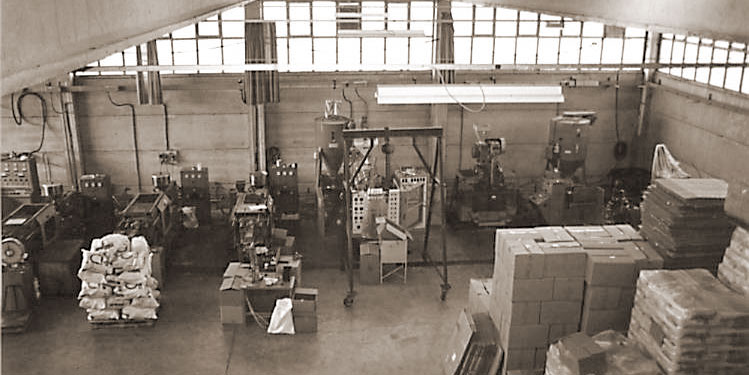

A new factory ready for operation

This is the year we get ready for one of the most awaited investments by all of us: we start producing tubes and decorating them with all the printing technologies available on the market. The thorough research of about technologies and machinery, together with the acquisition of knowlegde and professional skills, raise our determination in carrying out this new production and building up a new dedicated plant.

new energies

After about 2 years of work, we have developed a trigeneration system able to guarantee electric and thermal energy of great quality in full respect of the environment. Under the watchful eye of a supervisory system, all residual energy is reused.

automation 4.0

In 2010, we realised two of our major dreams: fully automated logistics and the distribution of plastic material. The entire production process is controlled by a MES system, that is integrated with the warehouse; 5 LGV vehicles (Laser Guided Vehicle) move the pallets of semi-finished and finished products; the plastic material is controlled, stored and distributed to the plants in a fully automatic way. This is to ensure a greater guarantee of quality and traceability to the customer.

100% made in Italy

While many manufacturers were moving their plants to Eastern Europe or Asia, we focused on the Made in Italy. We have expanded the plant, invested in the automation, the quality management and our creativity, continuing to to believe in the people and our territory.

cosmetic packaging

In the 90’s we decided to focus solely on packaging and to gradually abandon the production for third parties and technical articles. This journey has allowed us, over time, to create a catalogue of products that fully reflects our market vision and our packaging concept: an innovative product, of high quality and of high technical standing.

growth

The 80's were the years of: patents, the first European customers and the first acknowledgements. Ramaplast’s philosophy of a complete packaging offer is realised thanks to some acquisitions: finally the customer can focus solely on the product, leaving us the pleasure of thinking about the packaging.

new products

In order to widen the offer to the customer and strengthen the internal technical skills, it was then created the mechanical workshop (today Elettrostampi) followed by the purchase of the first blow moulding equipment.

From the first ideas of the initial group and a growing knowledge of the market result the first products in our catalogue, entirely designed, planned and manufactured in-house.

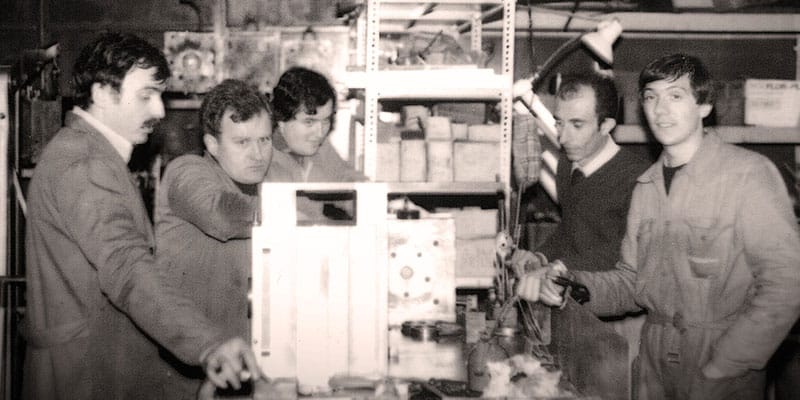

The adventure begins...

In 1973, a family decides to start working plastic materials for third parties, providing to the client their technical expertise

developed in the plastic and mechanical sector over the years.

The group is composed by Armando, Rosangela, Renzo, Giuseppe, Renato and Roberto;

the first workshop and the first press are located in the family barn in Castelnuovo Scrivia.